1-K PU foam pro B3

1C assembly foam PUR universal

ASMBYFM-1C-UNI-MAN-B3-750ML

Art.-no. 0892188020

EAN 4056807627816

Register now and access more than 125,000 products

- Pre-foaming

- Good insulation characteristics

- High thermal and acoustical insulation

- High adhesion to most building materials

- Excellent stability

- Filling joints cracks and gaps in insulating panels and sheets

- Excellently suitable as foam for sealing and connecting precast concrete well shaft rings

- CFC-free & harmless to the ozone layer

This information is only intended as a recommendation based on our own experience. The use should always perform his own preliminary testing.

Datasheets(X)

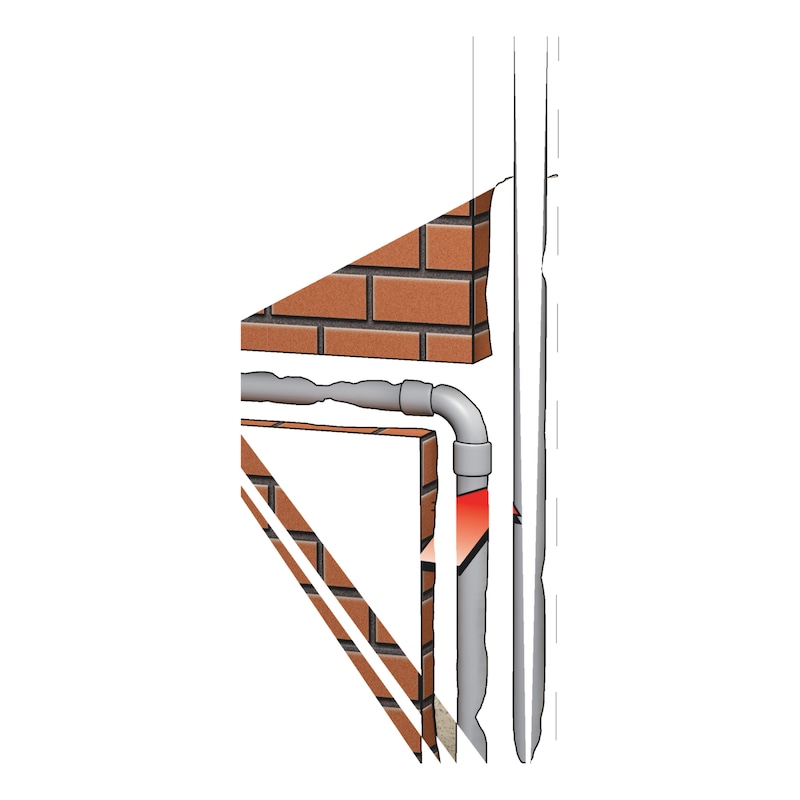

- Installing, fixing and insulating of door and window frames

- Filling and sealing of gaps, joint, openings and cavities

- Connecting of insulation materials and roof construction

- Installing, fixing and insulating of door and window frames

- Clean with a cleaning agent, to keep the substrate surfaces completely clean.

- Shake the can for over 1 mins.

- Fill vertical gaps from the bottom up (pay attention to foam expansion).

- Turn off the flow adjustment screw clockwise direction when finishing.

- Before curing, foam can be moved and cleaned with PU cleaner either with the gun or with adapter. Cleaning of the screw adapter with cleaner is recommended.

Chemical basis | Polyurethane |

Colour | Light yellow |

Density | 20 kg/m³ |

Density conditions | at 23°C, 50% relative humidity |

Moulded density | 1 g/cm³ |

Cell structure | Medium - fine |

Tack-free after | 12 min |

Conditions for being tack-free | at 20°C and 65% humidity |

Can be cut after | 50 min |

Conditions for ability to cut | at 20°C and 65% relative humidity at 30-mm adhesive line |

Full resilience | 2 min |

Min. processing temperature | 5 °C |

Min. ambient processing temperature | 5 °C |

Min. surface processing temperature | 0 °C |

Max. processing temperature for can | 35 °C |

Min./max. temperature resistance | -20 to 90 °C |

Max. short-term temperature resistance | 80 °C |

Heat conductance λ | 0.046 W/(m*K) |

Flexural strength | 85 kPa |

Conditions for flexural strength | after 28 days, 23°C and 50% relative humidity |

Shear strength | 114 kPa |

Conditions for shear strength | in accordance with DIN 53427 |

Longitudinal compressive strength | 3 N/cm |

Compressive strength conditions | after 28 days, 23°C and 50% relative humidity |

Breaking elongation | 60 % |

Breaking elongation conditions | in accordance with ASTM D-412 |

Yield (volume) approx. | 38 l |

Conditions for yield | at 23°C and 50% humidity, in released form |

Contents | 750 ml |

Container | Aerosol can |

Weight of content | 725 g |

Building material class | B3 - Of high flammability |

Building material class conditions | in accordance with DIN 4102 |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | at 5°C to 25°C |